TSMC (TWSE: 2330, NYSE: TSM) today unveiled its newest

semiconductor process, advanced packaging, and 3D IC technologies

for powering the next generation of AI innovations with silicon

leadership at the Company’s 2024 North America Technology

Symposium. TSMC debuted the TSMC A16TM technology,

featuring leading nanosheet transistors with innovative backside

power rail solution for production in 2026, bringing greatly

improved logic density and performance. TSMC also introduced its

System-on-Wafer (TSMC-SoW™) technology, an innovative solution to

bring revolutionary performance to the wafer level in addressing

the future AI requirements for hyperscaler datacenters.

This year marks the 30th anniversary of TSMC’s North

America Technology Symposium, and more than 2,000 attended the

event, growing from less than 100 attendees 30 years ago. The North

America Technology Symposium in Santa Clara, California kicks off

TSMC Technology Symposiums around the world in the coming months.

The symposium also features an “Innovation Zone,” designed to

highlight the technology achievements of our emerging start-up

customers.

“We are entering an AI-empowered world, where artificial

intelligence not only runs in data centers, but PCs, mobile

devices, automobiles, and even the Internet of Things,” said TSMC

CEO Dr. C.C. Wei. “At TSMC, we are offering our customers the most

comprehensive set of technologies to realize their visions for AI,

from the world’s most advanced silicon, to the broadest portfolio

of advanced packaging and 3D IC platforms, to specialty

technologies that integrate the digital world with the real

world.”

New technologies introduced at the symposium include:

TSMC A16TM Technology: With TSMC’s

industry-leading N3E technology now in production, and N2 on track

for production in the second half of 2025, TSMC debuted A16, the

next technology on its roadmap. A16 will combine TSMC’s Super Power

Rail architecture with its nanosheet transistors for planned

production in 2026. It improves logic density and performance by

dedicating front-side routing resources to signals, making A16

ideal for HPC products with complex signal routes and dense power

delivery networks. Compared to TSMC’s N2P process, A16 will provide

8-10% speed improvement at the same Vdd (positive power

supply voltage), 15-20% power reduction at the same speed, and up

to 1.10X chip density improvement for data center products.

TSMC NanoFlexTM Innovation for Nanosheet

Transistors: TSMC’s upcoming N2 technology will come with TSMC

NanoFlex, the company’s next breakthrough in design-technology

co-optimization. TSMC NanoFlex provides designers with flexibility

in N2 standard cells, the basic building blocks of chip design,

with short cells emphasizing small area and greater power

efficiency, and tall cells maximizing performance. Customers are

able to optimize the combination of short and tall cells within the

same design block, tuning their designs to reach the optimal power,

performance, and area tradeoffs for their application.

N4C Technology: Bringing TSMC’s advanced technology to a

broader range of of applications, TSMC announced N4C, an extension

of N4P technology with up to 8.5% die cost reduction and low

adoption effort, scheduled for volume production in 2025. N4C

offers area-efficient foundation IP and design rules that are fully

compatible with the widely-adopted N4P, with better yield from die

size reduction, providing a cost-effective option for value-tier

products to migrate to the next advanced technology node from

TSMC.

CoWoS®, SoIC, and System-on-Wafer (TSMC-SoW™

): TSMC’s Chip on Wafer on Substrate (CoWoS®) has

been a key enabler for the AI revolution by allowing customers to

pack more processor cores and high-bandwidth memory (HBM) stacks

side by side on one interposer. At the same time, our System on

Integrated Chips (SoIC) has established itself as the leading

solution for 3D chip stacking, and customers are increasingly

pairing CoWoS with SoIC and other components for the ultimate

system-in-package (SiP) integration.

With System-on-Wafer, TSMC is providing a revolutionary new

option to enable a large array of dies on a 300mm wafer, offering

more compute power while occupying far less data center space and

boosting performance per watt by orders of magnitude. TSMC’s first

SoW offering, a logic-only wafer based on Integrated Fan-Out (InFO)

technology, is already in production. A chip-on-wafer version

leveraging CoWoS technology is scheduled to be ready in 2027,

enabling integration of SoIC, HBM and other components to create a

powerful wafer-level system with computing power comparable to a

data center server rack, or even an entire server.

Silicon Photonics Integration: TSMC is developing Compact

Universal Photonic Engine (COUPE™ ) technology to support the

explosive growth in data transmission that comes with the AI boom.

COUPE uses SoIC-X chip stacking technology to stack an electrical

die on top of a photonic die, offering the lowest impedance at the

die-to-die interface and higher energy efficiency than conventional

stacking methods. TSMC plans to qualify COUPE for small form factor

pluggables in 2025, followed by integration into CoWoS packaging as

co-packaged optics (CPO) in 2026, bringing optical connections

directly into the package.

Automotive Advanced Packaging: After introducing the N3AE

“Auto Early” process in 2023, TSMC continues to serve our

automotive customers’ needs for greater computing power that meets

the safety and quality demands of the highway by integrating

advanced silicon with advanced packaging. TSMC is developing

InFO-oS and CoWoS-R solutions for applications such as advanced

driver assistance systems (ADAS), vehicle control, and vehicle

central computers, targeting AEC-Q100 Grade 2 qualification by

fourth quarter of 2025.

About TSMC

TSMC pioneered the pure-play foundry business model when it was

founded in 1987, and has been the world’s leading dedicated

semiconductor foundry ever since. The Company supports a thriving

ecosystem of global customers and partners with the industry’s

leading process technologies and portfolio of design enablement

solutions to unleash innovation for the global semiconductor

industry. With global operations spanning Asia, Europe, and North

America, TSMC serves as a committed corporate citizen around the

world.

TSMC deployed 288 distinct process technologies, and

manufactured 11,895 products for 528 customers in 2023 by providing

broadest range of advanced, specialty and advanced packaging

technology services. The Company is headquartered in Hsinchu,

Taiwan. For more information please visit https://www.tsmc.com.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240424036229/en/

TSMC Spokesperson:

Wendell Huang

Senior Vice President and CFO

Tel: 886-3-505-5901

Media Contacts:

Nina Kao

Head of Public Relations

Tel: 886-3-563-6688 ext.7125036

Mobile: 886-988-239-163

E-Mail: nina_kao@tsmc.com

Michael Kramer

Public Relations

Tel: 886-3-563-6688 ext. 7125031

Mobile: 886-988-931-352

E-Mail: pdkramer@tsmc.com

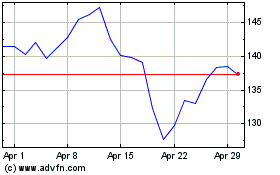

Taiwan Semiconductor Man... (NYSE:TSM)

Historical Stock Chart

From Mar 2024 to Apr 2024

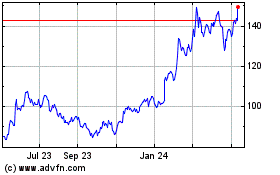

Taiwan Semiconductor Man... (NYSE:TSM)

Historical Stock Chart

From Apr 2023 to Apr 2024